Cleanliness in Dairy plants

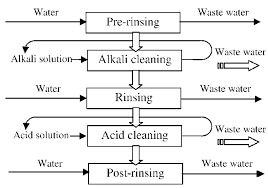

Cleanliness in dairy plants is critical for preventing microbial contamination and ensuring product safety, requiring regular, multi-step cleaning and sanitization of equipment, facilities, and staff. This includes daily rinsing and washing with specific alkaline and acid-based solutions, and periodic, thorough cleaning of all processing areas and bulk tanks using methods like Clean-In-Place (CIP) systems or manual disassembly, according to a strict sanitation schedule and Standard Operating Procedures (SOPs).

Key cleaning practices

Pre-rinse : A cold water rinse is necessary after each use to remove milk residues.

Washing : Use appropriate cleaning solutions.

Alkaline wash : Typically a caustic solution like sodium hydroxide is used, often at least twice a week and followed by an acid rinse.

Acid wash : Used regularly, for example, after every milking, to remove mineral build up and is often followed by a cold water rinse.

Hot wash : Must be carried out at least once a week using a hot caustic solution.

Sanitization : Apply chemical sanitizers, like chlorine-based solutions, at the recommended concentration for a specific contact time to kill bacteria before the next use.

Rinsing and draining : After washing and sanitizing, thoroughly rinse all equipment with water and ensure it is properly drained.

Facility and equipment cleaning

Milking parlours : Must be cleaned and disinfected at least twice daily, with surfaces regularly wiped down.

Bulk tanks : Large tanks can be cleaned manually or with automated CIP systems, but a cold water rinse must precede and follow the washing solution.

CIP systems : These automated systems clean equipment in place and are used for tanks, pipes, and other large processing equipment, ensuring thorough cleaning while minimizing employee exposure to chemicals.

Manual cleaning : For equipment that cannot be cleaned via CIP, it must be disassembled, cleaned with specific tools (e.g., color-coded brushes), and thoroughly washed, rinsed, and visually inspected before reassembly.

Staff and environment

Personnel : Train staff on proper hygiene protocols, cleaning procedures, and the use of appropriate Personal Protective Equipment (PPE) to avoid contamination and injury.

Animal hygiene : Ensure cows' udders are clean before milking using approved products.

General facility hygiene : Maintain clean housing, bedding, and ventilation for the animals to prevent dirt and bacteria from entering the milk supply.

Important considerations

Water quality : Monitor the quality of water used for cleaning and drinking to ensure it is free from contaminants.

Cleaning agents : Use only approved cleaning and sanitizing chemicals that have the correct concentration and application temperature, as specified by the manufacturer.

Documentation : Keep thorough records of all cleaning and sanitation activities as required for food safety compliance.